High Quality Best Injection Molding Hollow Parts Factory – CORAMWITE 1134-R & 1161-R & 6140-R – CORAM

High Quality Best Injection Molding Hollow Parts Factory – CORAMWITE 1134-R & 1161-R & 6140-R – CORAM Detail:

PDF

CORAMWITE 1134-R

CORAMWITE 1161-R

CORAMWITE 6140-R

CORAMWITE 1134-R

CORAMWITE 1134-R is a white general masterbatch for food contact, suitable for applications such as extrusion, injection molding and blow molding.

It uses high quality R-type titanium dioxide to offer outstanding pigmentation and opacifying performance. It has a good phase to the coloring material, featured by weatherability, heat resistance, migration resistance etc. It is suitable for use in a wide range of plastic products in contact with food.

Properties

| Carrier | PE |

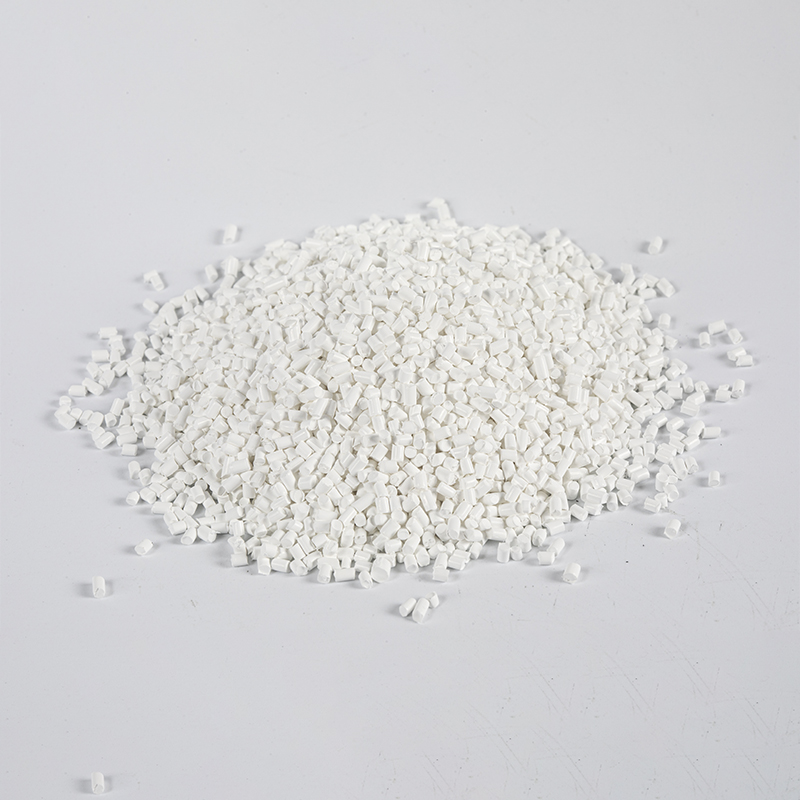

| Pellet Shape | Sphere/Cylinder |

| Pigment | 30%R-type Titanium Dioxide and 40% Calcium Carbonate |

| Compatibility | PE,PP |

| Bulk Density | 1.85-2.05 g/cm³ |

| MFI 10kg/190℃ | 20-30 g/10 min |

* Quoted test results should not be used for specification purposes but are typical test values intended for guidance only.

Method of Addition

CORAMWITE 1134-R is designed for ease of dilution and homogeneous mixing, therefore it`s suitable for direct addition using automatic dosing units or by pre-blending.

The amount of masterbatch added depends on the performance requirements of the final application. Typical addition rates vary from 1% to 5% masterbatch.The recommended dosage is 4%.

Packaging

CORAMWITE 1134-R is supplied in regular pellet form packed in 25kg bags. And it should be stored in a dry place.

Recommended storage life: Up to 1 year if stored as directed.

In compliance with statutory terms

| China | IECSC (Inventory of Existing Chemical Substances in China) |

| Europe | REACH (Regulation (EC) No. 1907/2006) |

| USA | TSCA (Toxic Substances Control Act) |

Advantage

1. We actively respond to any questions from customers and provide shorter delivery times. If customers have urgent needs, we will fully cooperate.

2. We focus on controlling the production process so that the performance of each batch is as consistent as possible and the product quality is excellent.

3. We cooperate with the best domestic freight forwarders to provide customers with sea, rail and air transportation and combined transportation solutions, and have plans for transportation difficulties caused by natural disasters, epidemics, wars

CORAMWITE 1161-R

CORAMWITE 1161-R is a white general masterbatch for food contact, suitable for applications such as extrusion, injection molding and blow molding.

It uses high quality R-type titanium dioxide to offer outstanding pigmentation and opacifying performance. It has a good phase to the coloring material, featured by weatherability, heat resistance, migration resistance etc. It is suitable for use in a wide range of plastic products in contact with food.

Properties

| Carrier | PE |

| Pellet Shape | Sphere/Cylinder |

| Pigment | 60%R-type Titanium Dioxide and 10% Calcium Carbonate |

| Compatibility | PE,PP |

| Bulk Density | 1.65-1.95 g/cm³ |

| MFI 10kg/190℃ | 25-35 g/10 min |

* Quoted test results should not be used for specification purposes but are typical test values intended for guidance only.

Method of Addition

CORAMBLAK 6025 is designed for ease of dilution and homogeneous mixing, therefore it`s suitable for direct addition using automatic dosing units or by pre-blending.

The amount of masterbatch added depends on the performance requirements of the final application. Typical addition rates vary from 1% to 5% masterbatch.The recommended dosage is 4%.

Packaging

CORAMBLAK 6025 is supplied in regular pellet form packed in 25kg bags. And it should be stored in a dry place.

Recommended storage life: Up to 1 year if stored as directed.

In compliance with statutory terms

| China | IECSC (Inventory of Existing Chemical Substances in China) |

| Europe | REACH (Regulation (EC) No. 1907/2006) |

| USA | TSCA (Toxic Substances Control Act) |

Advantage

1. We actively respond to any questions from customers and provide shorter delivery times. If customers have urgent needs, we will fully cooperate.

2. We focus on controlling the production process so that the performance of each batch is as consistent as possible and the product quality is excellent.

3. We cooperate with the best domestic freight forwarders to provide customers with sea, rail and air transportation and combined transportation solutions, and have plans for transportation difficulties caused by natural disasters, epidemics, wars and other factors.

CORAMWITE 6140-R

CORAMWITE 6140-R is a white general masterbatch for food contact, suitable for applications such as extrusion, injection molding.

It uses high quality R-type titanium dioxide to offer outstanding pigmentation and opacifying performance. It has a good phase to the coloring material, featured by weatherability, heat resistance, migration resistance etc. It is suitable for use in a wide range of plastic products in contact with food.

Properties

| Carrier | AS |

| Pellet Shape | Sphere/Cylinder |

| Pigment |

40%R-type Titanium Dioxide |

| Compatibility | AS,ABS,PC |

| Bulk Density | 1.85-2.05 g/cm³ |

| MFI 5kg/200℃ | 10-20 g/10 min |

* Quoted test results should not be used for specification purposes but are typical test values intended for guidance only.

Method of Addition

CORAMWITE 6140-R is designed for ease of dilution and homogeneous mixing, therefore it`s suitable for direct addition using automatic dosing units or by pre-blending.

The amount of masterbatch added depends on the performance requirements of the final application. The recommended dosage is 4%.

Packaging

CORAMWITE 6140-R is supplied in regular pellet form packed in 25kg bags. And it should be stored in a dry place.

Recommended storage life: Up to 1 year if stored as directed.

In compliance with statutory terms

| China | IECSC (Inventory of Existing Chemical Substances in China) |

| Europe | REACH (Regulation (EC) No. 1907/2006) |

| USA | TSCA (Toxic Substances Control Act) |

Advantage

1. We actively respond to any questions from customers and provide shorter delivery times. If customers have urgent needs, we will fully cooperate.

2. We focus on controlling the production process so that the performance of each batch is as consistent as possible and the product quality is excellent.

3. We cooperate with the best domestic freight forwarders to provide customers with sea, rail and air transportation and combined transportation solutions, and have plans for transportation difficulties caused by natural disasters, epidemics, wars and other factors.

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of High Quality Best Injection Molding Hollow Parts Factory – CORAMWITE 1134-R & 1161-R & 6140-R – CORAM , The product will supply to all over the world, such as: Panama, Denmark, Kenya, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.