High Quality Best Copper Silver Plated Factories – CAMK52100 Tin Phosphor Bronze Coil or Bar or Strip – CORAM

High Quality Best Copper Silver Plated Factories – CAMK52100 Tin Phosphor Bronze Coil or Bar or Strip – CORAM Detail:

Material Designation

| GB | T2QSn8-0.3 |

| UNS | C52100 |

| EN | CW453K |

| JIS | C5212 |

Chemical Composition

| Copper, Cu | Rem. |

| Stannum, Sn | 7.50 – 8.50% |

| Phosphorus, P | 0.01 – 0.40% |

| Iron, Fe | Max. 0.10% |

| Nickel, Ni | Max. 0.20% |

| Plumbum, Pb | Max. 0.02% |

Physical Properties

| Density | 8.80 g/cm3 |

| Electrical Conductivity | Min. 13 %IACS |

| Thermal Conductivity | 62.3 W/( m·K) |

| Melting Point | 1027 ℃ |

Characteristics

CAMK52100 is a copper-tin-phosphorus ternary alloy with high tin content. A small amount of (α+δ) eutectoid will be produced in the α phase solid solution of the alloy structure. The δ phase is a hard and brittle phase, which improves the mechanical properties of the alloy. performance, wear resistance. At the same time, due to the addition of phosphorus element, the corrosion resistance of the alloy is improved.

CAMK52100 has high strength, hardness, high elasticity and wear resistance. High corrosion resistance in atmosphere, fresh water and sea water, easy to weld.

Application

CAMK52100 is mainly used for friction-bearing parts under moderate loads and sliding speeds, but also for elastic elements such as springs and reeds.

Mechanical Properties

|

Specification mm (up to) |

Temper |

Tensile Strength Min. MPa |

Yield Strength Min. MPa |

Elongation Min. A% |

Hardness Min. HRB |

|

φ 20-50 |

Y2 |

450 |

280 |

26 |

/ |

|

φ 50-100 |

Y2 |

400 |

280 |

26 |

/ |

|

>φ 100 |

TF00/TB00 |

Please send an email to ryan@corammaterial.com for more details. |

|||

Advantage

1. We actively respond to any questions from customers and provide shorter delivery times. If customers have urgent needs, we will fully cooperate.

2. We focus on controlling the production process so that the performance of each batch is as consistent as possible and the product quality is excellent.

3. We cooperate with the best domestic freight forwarders to provide customers with sea, rail and air transportation and combined transportation solutions, and have plans for transportation difficulties caused by natural disasters, epidemics, wars and other factors.

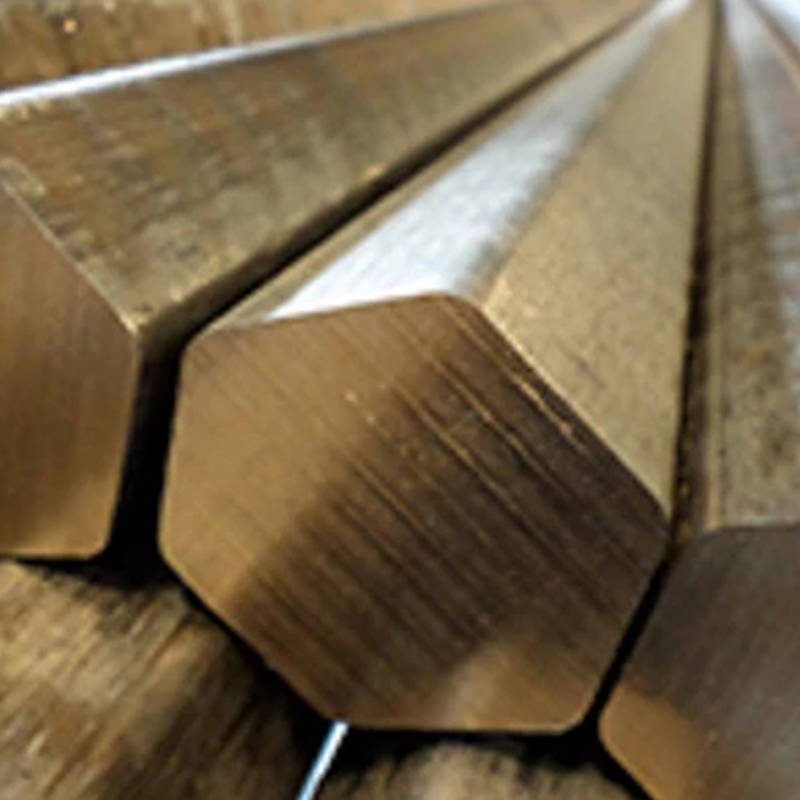

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for High Quality Best Copper Silver Plated Factories – CAMK52100 Tin Phosphor Bronze Coil or Bar or Strip – CORAM , The product will supply to all over the world, such as: Romania, Ukraine, Nairobi, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!